1. Introduction

1.1 Definition

The Pharmaceutical Quality by Design (QbD) is a systematic approach to development that

begins with predefined objectives and emphasizes product and process understanding and

process control, based on sound science and quality risk management. Quality by Design

(QbD) is emerging to enhance the assurance of safe, effective drug supply to the consumer

and also offers promise to significantly improve manufacturing quality performance.

1.2 Regulatory Requirements:

The concept of “Quality by Design” (QbD) was defined as an approach which covers a better

scientific understanding of critical process and product qualities, designing controls and tests

based on the scientific limits of understanding during the development phase and using the

knowledge obtained during the life-cycle of the product to work on a constant improvement

environment. QbD describes a pharmaceutical development approach referring to

formulation design and development and manufacturing processes to maintain the prescribed

product quality. Guidelines and mathematical models are used to ensure the establishment

and use of the knowledge on the subject in an independent and integrated way.

Within this vision, the key framework guidance documents ICH Q8 Pharmaceutical

Development and ICH Q9 Quality Risk Management were published in 2005 and ICH Q10

Pharmaceutical Quality System followed these documents in 2008. Q8 Pharmaceutical

Development focuses on the content of the Module 3.2.P.2 of the Common Technical

Document (CTD) and promotes the concept of QbD. Final guideline Q8(R)2 was published

in 2008. It supports knowledge gained through the lifecycle of a product and using scientific

approaches and quality risk management principles. Within the scope of Q8 Pharmaceutical

Development, an important step in the QbD approach to the development of drug products

requires a distinction between critical and non-critical product attributes and process

parameters.

Additionally, the quality target product profile (QTTP) is defined as a summary of the quality

characteristics or attributes of a product that ideally will be achieved and is related to quality,

safety and efficacy, considering the route of administration, dosage form, bioavailability,

strength, and stability.

The ICH guideline Q9 Quality Risk Management defines risk and offers a systematic

approach to quality risk management via describing how to conduct risk assessments and to

manage the risks defined providing guidance on the principles and some of the tools of

quality risk management. It can be a guide as a resource document that is independent of, yet

supporting, other ICH Quality documents and complementing existing quality practices,

requirements, standards, and guidelines within the pharmaceutical industry and regulatory

framework.

The ICH guideline Q10 describes a model for an effective pharmaceutical quality system

that is based on International Standards Organization (ISO) quality concepts, includes

applicable GMP regulations and complements ICH Q8 and ICH Q9, and is applicable for a

lifecycle of a product.

This guideline focuses on regulating the quality management systems of drug manufacturers;

where by any changes to manufacturing processes would be managed by appropriate change

control procedures have been developed.

Although the initial focus of the science and risk based agenda was linked primarily to drug

product, greater emphasis is now being placed on drug substance with the evolution of ICH

Q11 dedicated to the manufacture of drug raw materials. Recent regulatory initiatives such as

Quality-by-Design provided unprecedented opportunities to go beyond what was done in the

past. The guideline focuses on development and manufacturing process of both chemical and

biotechnological/biological drug substances and is intended to provide guidance in the scope

of ICH Guideline Q6A and Q6B. If the principles described in the ICH Q8, Q9 and Q10

guidance documents are implemented together in a holistic manner, then an effective system

that emphasizes a harmonized science and risk-based approach to product development and

maintenance is in place. This provides an even greater (quality) assurance that the patient

will receive product that meets the critical quality attributes (CQA).

1.3 Key Characteristics of QbD

A tool for focused & efficient drug development.

Dynamic and systematic process.

Relies on the concept that Quality can be built in as a continuum.

It is applicable to Drug Product and Drug Substance development (chemicals / biologics).

It is applicable to analytical methods.

Can implement partially or totally.

Can be used at any time in the life cycle of the Drug.

Always encouraged by Regulators.

1.4 Advantages of QbD

Benefits for Industry:

Better understanding of the process.

Less batch failure.

More efficient and effective control of change.

Return on investment / cost savings.

1.5 Factors impeding implementation on A QbD

Complete understanding of A QbD is still lacking in the pharmaceutical industry.

Proper definitions of the MODR, ATP, analytical method control strategy, and method

performance criteria and other elements of AQbD must be given. Global harmonization of

these terminologies is a must.

Revision of ICH guideline Q2 (R1) requires revision to include AQbD elements.

Additional guidelines need to be developed for implementation of AQbD.

Analysts must learn new tools and skills.

A consistent worldwide approach is required for this initiative to be effective.

1.6 Additional opportunities:

An enhance QbD approach to pharmaceutical development provides opportunities for

more flexible regulatory approaches. Ex: Manufacturing changes within the approved

design space without further regulatory review.

Reduction of post-approval submissions.

Better innovation due to the ability to improve processes without resubmission to the

FDA when remaining in the Design Space.

More efficient technology transfer to manufacturing.

Greater regulator confidence of robust products.

Risk-based approach and identification.

Innovative process validation approaches.

Less intense regulatory oversight and less post-approval submissions.

For the consumer, greater drug consistency.

More drug availability and less recall.

Improved yields, lower cost, less investigations, reduced testing, etc.

Time to market reductions: from 12 to 6 years realized by amongst others.

First time right: lean assets management.

Continuous improvement over the total product life cycle (i.e. controlled, patient guided

variability).

Absence of design freeze (no variation issues).

Less validation burden.

Real time controls (less batch controls).

Realistic risk perceptions.

Contributes substantially to realize the better, cheaper and safer mandate.

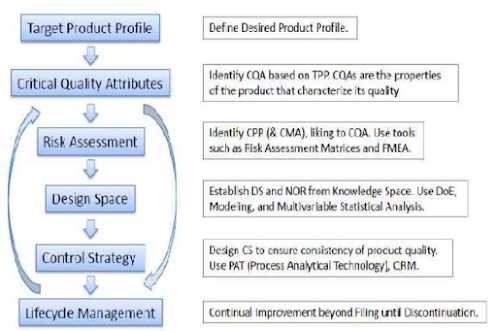

1.7 Implementation of QbD

A framework for applying QbD to analytical methods: QbD can be applied equally to

processes and analytical. It displays how QbD for methods, analytical methods are driven by

the overall process.

Method performance requirements (Design intent): Fundamental to any method

development is being clear about the design intent of the method (i.e., the criteria that must

be met). Method-performance criteria and method-operational intent are two important

aspects of this design intent.

Method performance criteria: These criteria are driven by an understanding of the

process monitoring and control requirements; that is, the process critical quality attributes

(CQAs) and specification limits. CQAs are identified, through a thorough understanding of

those characteristics of a drug substance or a drug product that may need to be controlled to

ensure the safety or efficacy of a product. For methods measuring these CQAs, criteria, such

as the following would need to be met. Precision—the need for method variability to be a

small proportion of the specification. Selectivity—being clear on which impurities actually

need to be monitored at each step in a process and ensuring adequate discrimination between

them. Sensitivity-ensuring the method is sufficiently sensitive relative to the specification

limit. PAT methods often meet the criteria above in a different way from traditional endpoint

testing methods such as high-performance liquid chromatography (HPLC). Selectivity,

for example, may be achieved through a multivariate model as opposed to the resolution

between adjacent peaks in an HPLC method. For these methods, precision could be

demonstrated by checking the predictive validity of the model.

Method operational intent: These criteria address the aspects of the method that are

required to facilitate ease of use in routine operation (e.g., analysis time, acceptable solvents,

and available equipment). Opportunities for the implementation of improved or new

technology also may be identified. These criteria can be generated by performing an analysis

of the voice of the customer (VoC) (i.e., the aspects of a method that are considered important for the quality control laboratories within manufacturing where the commercial

methods will be operated)

Method development (design selection): Fundamental to design selection is the methoddevelopment

phase. To develop a QbD method, the method performance criteria must be

understood as well as the desired operational intent that the eventual end user would wish to

see in the method.

1.8 QbD development process includes:

2. Elements of QbD

2.1 Quality target product profile (QTPP)

It is defined as a “prospective and dynamic summary of the quality characteristics of a

drug product that ideally will be achieved to ensure that the desired quality, andthus the

safety and efficacy, of a drug product is realized”. Basically it is a tool for setting the strategy

for drug development.

Recently QTTP is widely used in development planning, clinical and commercial

decision making, regulatory agency interactions, and risk management.

It is the quality characteristics that the drug product should possess in order to

reproducibly deliver the therapeutic benefit promised in the label.

The QTTP guides formulation scientists to establish formulation strategies and keep the

formulation effort focused and efficient.

QTPP is related to identity, assay, dosage form, purity, stability in the label.

The quality target product profile forms the basis of design for the development of the

product. Considerations for the quality target product profile could include:

Intended use in clinical setting, route of administration, dosage form, delivery systems;

Dosage strength(s);

Container closure system;

Therapeutic moiety release or delivery and attributes affecting pharmacokinetic

characteristics (e.g., dissolution, aerodynamic performance) appropriate to the drug product

dosage form being developed;

Drug product quality criteria (e.g., sterility, purity, stability and drug release) appropriate

for the intended marketed product.

2.2 Critical Quality Attributes (CQA)

Once TPQP has been identified, the next step is to identify the relevant CQAs.

A CQA is a physical, chemical, biological,or microbiological property or characteristic

that should be within an appropriate limit, range, or distribution to ensure the desired product

quality. CQAs are generally associated with the drug substance, excipients, intermediates (inprocess

materials) and drug product.

CQAs of solid oral dosage forms are typically those aspects affecting product purity,

strength, drug release and stability. CQAs for other delivery systems can additionally include

more product specific aspects, such as aerodynamic properties for inhaled products, sterility

for parenterals, and adhesion properties for transdermal patches. For drug substances, raw

materials and intermediates, the CQAs can additionally include those properties (e.g., particle

size distribution, bulk density) that affect drug product CQAs.

Potential drug product CQAs derived from the quality target product profile and/or prior

knowledge is used to guide the product and process development. The list of potential CQAs

can be modified when the formulation and manufacturing process are selected and as product

knowledge and process understanding increase.

Quality risk management can be used to prioritize the list of potential CQAs for

subsequent evaluation. Relevant CQAs can be identified by an iterative process of quality

risk management and experimentation that assesses the extent to which their variation can

have an impact on the quality of the drug product.

The use of robust risk assessment methods for identification of CQAs is novel to the QbD

paradigm CQAs of solid oral dosage forms are typically those aspects affecting product

purity, strength, drug release and stability.

CQAs for other delivery systems can additionally include more product specific aspects,

such as aerodynamic properties for inhaled products, sterility for parenteral, and adhesion

properties for transdermal patches.

2.3 Critical Process Parameter

Critical process parameters (CPPs) are defined as “parameters whose variability have an

impact on a CQA and therefore should be monitored or controlled to ensure the process

produces the desired quality.

A parameter is critical when a realistic change in that parameter can cause the product to

fail to meet the QTPP. Thus, whether a parameter is critical or not depends on how large of a

change one is willing to consider.

Process robustness is defined as the ability of a process to demonstrate acceptable quality

and performance and tolerate variability in inputs at the same time. To demonstrate the

reproducibility and consistency of a process, process capability should be studied. Process

capability is a statistical measure of the inherent process variability for a given

characteristics.

The most widely accepted formula for process capability is six sigma.

Process capability index is the value of the tolerance specified for a particular

characteristic divided by the process capability, which is defined as follows:

Process capability index (CpK) = Upper limit of specification - Lower limit of specification

6 standard deviation

If the CpK is significantly greater than one, the process is defined capable. If the process

capability is low, there are five step procedures to progressively reduce the variability of the

process.

These five steps are:

I. Define: The intended improvement should be clearly stated.

II. Measure: The critical product performance attributes should be measured to see if they are

out of specification and used to the sigma level of the process.

III. Analyze: When the sigma level is below the target, steps should be taken to increase it,

starting by identifying the most significant causes of the excessive variability.

IV. Improve: The process should be redesigned and/ or process controls should be

incorporated to eliminate or attenuate the significant toot causes of variance.

V. Control: The improved manufacturing process should be evaluated and maintained.

2.4 Risk assessment

Quality risk management is a systematic process for the assessment, control,

communication and review of risks to the quality of the drug (medicinal) product across the

product lifecycle.

The initial list of potential parameters which can affect CQAs can be quite extensive but

can be reduced and prioritized by quality risk assessment (QRA).

QRA is a science based process that can aid identification of CPPs and thus eliminating

risk, resulting in high confidence that the analytical method will meet the QTTP under all

conditions of use.

Thus, a large number of parameters can actually be safely eliminated by use of QRA

tools, for example failure mode effects analysis (FMEA) and Ishikawa diagrams on the basis

of prior knowledge and initial experimentation.

In FMEA the variables are ranked on the basis of the likelihood failure will occur

(probability), affect on the pharmaceutical results (severity), and difficulty of detection

(detectability), resulting in a risk priority number (RPN).

Factors with an RPN above a cut-off level can then be evaluated by subsequent studies

whereas factors with a lower RPN can be eliminated from further study.

Ishikawa diagrams segregate risks into different categories, for example those associated

with instrumentation, materials, methods, measurements, laboratory climate, and human

factors.

2.5 Design Space

The ICH Q8 (R2) states that the design space is multidimensional combination and

interaction of input variables (e.g., material attributes) and process parameters that have been

demonstrated to provide assurance of quality.

Working within the design space is not considered as a change. Movement out of the

design space is considered to be a change and would normally initiate a regulatory post

approval change process.

Design space may be constructed for a single unit operation, multiple unit operations, or

for the entire process.

Though according to FDA guideline, defining design space is optional since the product

and process understanding can be established without a formal design space, nevertheless,

such approach can assist to better understanding and attain overall control of a system.

Design space is proposed by the applicant and is subject to regulatory assessment and

approval.

It describes the multivariate functional relationships between CQAs and the CPPs that

impact them, and should include their linkage to or across unit operations.

Such relationships are arrived at by iterative application of risk assessment and

experimental design, modeling, as well as the use of literature and prior experience.

Methods for determining design space included: one-variable-at-a-time experiments,

statistically designed experiments, and modeling approaches.

Methods for presenting design space included graphs (surface-response curves and

contour plots), linear combination of parameter ranges, equations, and models.

Design space is potentially scale and equipment dependent, the design space determined

on the laboratory scale may not be relevant to the process at the commercial scale. Therefore,

design-space verification at the commercial scale becomes essential unless it is confirmed

that the design space is scale-independent.

2.6 Control Strategy

The ability to evaluate and ensure the quality of in-process and/or final product based on

process data which typically include a valid combination of measured material attributes

and process controls. ICH Q8 (R2).

Control strategy is defined as “a planned set of controls, derived from current product and

process understanding that assures process performance and product quality”.

The control strategy in the QbD paradigm is established via risk assessment that takes

into account the criticality of the CQA and process capability.

DOE results can help identify optimal conditions, the critical factors that most influence

CQAs and those who do not, as well as details such as the existence of interactions and

synergies between factors. The control strategy can include the following elements:

procedural controls, in-process controls, lot release testing, process monitoring,

characterization testing, comparability testing and stability testing.

Particularly, the control strategy may include:

Control of raw material attributes (e.g., drug substance, excipients and primary

packaging materials) based on an understanding of their impact on process-ability

or product quality.

Product specifications

Procedural controls

Facility controls such as utilities, environmental systems and operating conditions

Controls for unit operations that have an impact on downstream processing or

end-product quality (e.g. the impact of drying on degradation, particle size

distribution of the granulate on dissolution).

2.7 Life Cycle Management

In the QbD paradigm, process changes within the design space will not require review or

approval.

Therefore, process improvements during the product life cycle with regard to process

consistency and throughput could take place with fewer post approval submissions.

In addition to regulatory flexibility, the enhanced understanding of the manufacturing

process would allow more informed risk assessment as per ICH Q9 regarding the affects

of process changes and manufacturing deviations (excursions) on product quality.

Nice bro this content is very use ful

ReplyDeleteThanks....

Delete